- Home

- Products

- Drilling Tapping Machine (for Dining Sets)

- Automatic Chamfering Drilling Tapping Machine

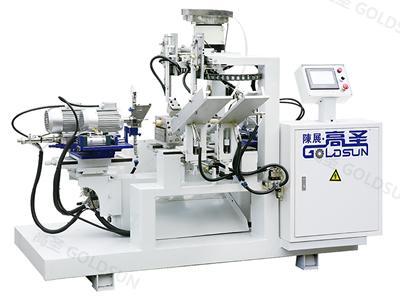

Automatic Chamfering Drilling Tapping Machine

Description

The automatic chamfering drilling tapping machine is used for chamfering, drilling and tapping processes for the production of dining tables and chairs. Each process can be continuously carried out, and the vibrating disk will automatically feed screws into the machine. Workers need only unload the workpieces at the end.

This machine can complete 5-6 pieces in one minute, and up to 2,000 pieces in 8 hours, thus saving production costs and time.

Parameters| Cutter shaft power | 2HP |

| Tapping power | 1HP |

| Drilling power | 1HP |

| Servo power | 0.4KW |

| Machine size | 1400*1100*1300mm |

| Weight | 400kg |

- The chamfering, drilling and tapping actions are all consecutive, ensuring the chamfering edge is smooth and the hole position is accurate. This ensures the machine is both efficient and safe.

- This machine is easy to control. Users need only to load or unload the machine, and a single employee can simultaneously operate two machines.

- The machine is designed with a compact, space saving structure.

- The user interface is clear and easy to operate.

- The high-quality motors make operation smooth and stable.

- The electric circuit is designed to showcase its quality, and makes operation simple and convenient.

- Chamfer the timbers.

- Drill the first hole.

- Drill the second hole.

- Tap the first thread.

- Tap the second thread.

- Vibrating disk feed screws.

- Chamfer, drill and tap the tables and chairs.

Inquiry Form

Dongguan Chenzhan Machinery Co., Ltd.

Add.: No.2, Fourth Street, Chaye Road, 3rd Industrial area, Dalingshan Town, Dongguan, Guangdong province

Fax: +86-769-82930021